Printing technology has advanced greatly in the digital age, providing numerous options for use in many different fields. Recent years have seen a rise in the use of DTF printing, one such printing method.

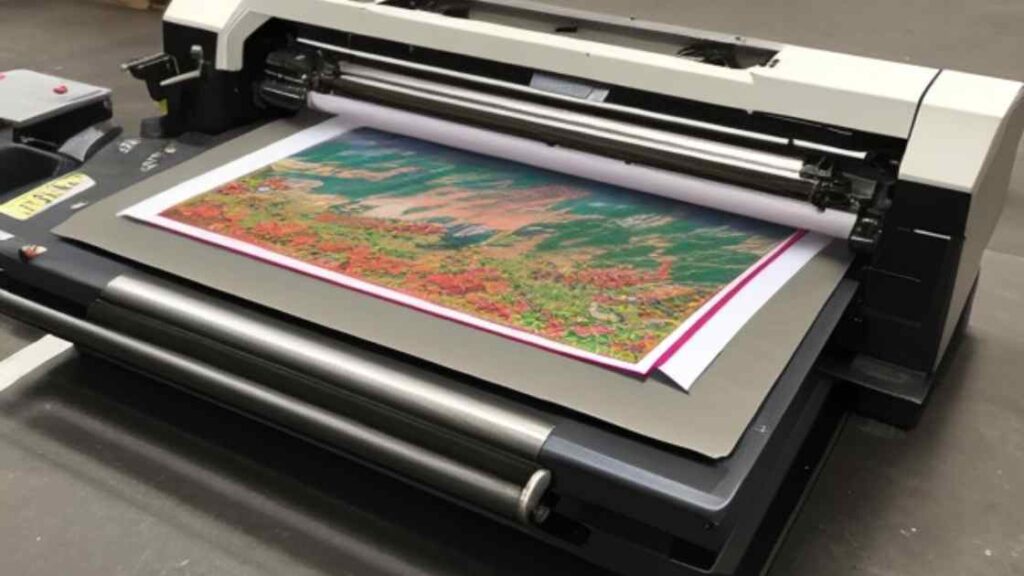

Direct-to-Film (DTF) printing is a modern printing method that has enabled high-quality, long-lasting prints to be made on a variety of materials, such as textiles, plastics, and more.

Google reports that DTF printing’s popularity is on the rise because more and more people and companies are looking for a low-cost and dependable printing option. In this article, we will discuss DTF printing in further detail, including what it is, how it operates, and the various uses it has.

What is DTF printing and How does DTF printing work ?

Direct-to-Film (DTF) printing is a method of printing in which designs are printed directly onto a special heat transfer film, which can then be applied to a garment or other surface using a heat press. Typically, the design is printed onto the film using a specialised DTF printer that combines ink and pigment to produce vibrant, long-lasting prints.

The printed film is then cut to size and heat-pressed onto the garment, transferring the design from the film to the fabric. DTF printing is a popular option for creating custom apparel because it permits full-color designs with intricate details and gradients, as well as printing on a range of fabrics and surfaces.

Related: What is DTG Printing ? Learn Everything About DTG Printing.

Additionally, the process is relatively quick and cost-effective, making it a popular option for both small- and large-scale printing initiatives.

How to Use a DTF printer ?

A DTF printer, or Direct-to-Film printer, is a specialized printer used for printing designs on heat transfer film. Here are the general steps for using a DTF printer:

Here’s how the DTF printing process typically works:

- Prepare your design: Utilize a programme for graphic design, such as Adobe Illustrator or CorelDRAW, to create or modify your design. Set the colour mode to CMYK to ensure accurate colour reproduction. Adapt the design’s resolution and dimensions to the printer’s specifications. You can also use pre-made designs or templates.

- Load the transfer film: Cut the transfer film to the correct dimension and load it onto the platen of the printer. Ensure that the film is straight and rigid, with no creases or wrinkles. Clip it or secure it with adhesive tape.

- Print the design: Before printing the design, adjust the printer’s settings, including resolution, colour profile, and ink density. DTF printers use white ink as an underbase layer to increase the colour’s saturation and opacity. The white layer is printed first, followed by the colour layers.

- Cure the ink: After printing, the ink must be cured to assure proper adhesion to the transfer film. For this procedure, you can utilise a heat press or a conveyor dryer. Temperature and curing time are dependent on the type of ink and the substrate. Consult the manufacturer’s guidelines for recommended parameters.

- Cut the transfer film:Remove the transfer film from the printer and trim it with a vinyl cutter or a plotter once the pigment has cured. If you do not have a cutting machine, you may also use scissors or a hobby knife. Be cautious not to sever the design.

- Transfer the design: Remove any moisture or wrinkles from the garment with a thermal press before transferring the design. Place the transfer film with the printed side facing down on top of the garment. Apply heat and pressure according to the instructions on the transfer film. Carefully remove the transfer film while it is still heated.

Direct to Film Printing Pros and Cons

HTV Vs DTF

HTV (Heat Transfer Vinyl) and DTF (Direct to Film) are two popular methods of printing designs onto fabrics. Here is a detailed comparison between the two:

- Process: The procedure utilized to transfer the design onto the cloth is the primary distinction between HTV and DTF. HTV includes cutting a design from vinyl material and applying it to the fabric with heat and pressure. DTF, on the other hand, entails printing the design onto a specific film, which is then heated and pressed onto the fabric.

- Design complexity: Design complexity: Because the vinyl material cannot handle elaborate features or small writing, HTV is best suited for simple designs with fewer colors. DTF, on the other hand, has the ability to handle more complicated designs with higher detail and color fidelity. DTF printing technology enables more complex designs to be printed in a single pass, resulting in a higher-quality end product.

- Fabric compatibility: HTV is compatible with a wide range of materials, including cotton, polyester, and mixes. However, it may not adhere well to some difficult-to-print textiles, such as nylon or silk. DTF can be used with a wider variety of textiles, including cotton, polyester, nylon, and even leather.

- Image quality: DTF generates higher-quality images with better color accuracy and vibrancy than HTV. DTF also enables more precise color registration, resulting in a more professional-looking finished output.

- Durability: HTV and DTF are both long-lasting and can endure repeated washing and wearing. However, because the ink is incorporated directly into the fabric fibers, DTF may be slightly more durable, whereas HTV lies on top of the fabric and may peel with time.

- Cost: Because it involves fewer ingredients and less specialized equipment, HTV is often less expensive than DTF. DTF necessitates the use of a specialist printer, ink, and film, which might be more expensive than HTV.

In summary, both HTV and DTF have benefits and drawbacks, and which method is better for a specific project depends on aspects such as design complexity, fabric type, and required image quality.

Related: DTF Vs Sublimation: Ultimate Comparison.

How Long Does DTF last on shirts ?

DTF (Direct-to-Film) printing is a relatively new printing method that uses a specialized printer to print designs directly onto a transfer film, which is then heat pressed onto a garment.

The durability of DTF printing on shirts can vary depending on various factors such as the quality of the ink, the type of garment, and the care and maintenance given to the shirt. However, generally speaking, DTF printing is known for its excellent durability and longevity compared to other printing methods such as DTG (Direct-to-Garment) printing.

Also Read: What is Monochrome Printing ? Detailed Guide (2023)

With proper care and washing, DTF printed shirts can last for many years without fading or cracking. It is recommended to wash DTF printed shirts in cold water and to avoid using bleach or fabric softeners.

What can DTF be applied to ?

DTF printing, sometimes referred to as Direct to Film printing can be used to transfer the picture to a variety of materials, including fabric, ceramics, glass, metal, and others.

DTF printing is useful for a variety of products and sectors, including:

- Apparel and textiles –DTF printing is frequently used to manufacture bespoke t-shirts, hats, and other fashion items. It can also be used to print designs on fabric for home décor items like curtains, bedspreads, and upholstery.

- Signage and advertising –DTF printing is great for producing high-quality signage and promotional materials such as banners, posters, and decals.

- Promotional items – DTF printing can be used to make promotional items like mugs, keychains, and phone cases.

- Automotive and aerospace – DTF printing can be used to print designs on a variety of automotive and aerospace parts and components.

- Packaging and labels – DTF printing is suitable for producing high-quality product packaging and labels.

Freuently Asked Questions

Q: What is the cost of DTF printing compared to other printing methods?

When compared to other printing methods, the cost of DTF printing can vary based on things like the size of the design, the number of colors used, and the number of items ordered. Most people think that DTF printing is cheaper than other ways like screen printing or direct-to-garment printing. But DTF printing may be more expensive than other ways such as vinyl printing or heat transfer printing.

Q: What is the resolution and quality of DTF printing?

DTF printing can have a high resolution and quality, so it can print pictures that are clear, bright, and have fine details. DTF printing uses modern digital printing technology, which makes it possible to print with a high resolution and a wide range of colors. Several things can affect the quality of DTF printing, such as the quality of the transfer film, the type of ink used, and the surface where the transfer is put.

Q: Can DTF printing be used for mass production?

DTF printing is a popular choice for companies that need to print a lot of things because it can be used for mass production. DTF printing is great for mass production because it is fast and works well. This means that production can be done quickly and cheaply. But the speed of production can be slowed or sped up by things like the size of the image and how complicated the printing process is.

Conclusion

In conclusion, DTF printing is a relatively new and innovative printing technology that lets users print high-quality images straight onto a transfer film, which can then be used to transfer the image onto different surfaces. This way of printing is flexible, cheap, and can be used for many different products and industries. DTF printing is becoming more and more popular with both businesses and people because it can print in high resolution and make prints that last for a long time.