Nylon, a standard synthetic fabric, is valued for its longevity and adaptability. Nylon is widely used in many fields, from sportswear to camping equipment. But when it comes to personalization, there are concerns about whether or not nylon can be sublimated on the surface.

It’s more complicated than just saying yes or no. Several variables come into play, including the nylon, ink, and sublimation technique.

To help individuals interested in personalizing nylon goods, this guide will investigate the issue, “Can you sublimate on nylon?”

What type of nylon is best for sublimation?

Not all nylons are created equal for sublimating. White nylon covered with polyester works best for sublimation. This nylon is developed to accept sublimation ink and to prevent the ink from smearing or bleeding during the process of sublimation on nylon.

The polyester coating on the nylon creates a flat, level surface ideal for transferring intricate, colorful graphics. However, not all polyester-coated nylon fabrics are made equal; testing the material is essential before beginning the process of sublimation on nylon to guarantee the best possible results.

Note: It’s important to note that while sublimation on nylon and other types of nylon may be possible, including nylon blends and uncoated nylon, the results may be less vibrant and long-lasting than they would be on polyester-coated nylon.

Can nylon withstand heat press?

Sublimation on nylon is heat resistant. Therefore the answer is yes. The ink is transferred from a paper or film into the nylon fabric using heat and pressure during the process of sublimation on nylon, making the pattern an integral rather than a surface feature of the fabric.

The molecules of the ink fuse with the nylon fibers, producing a permanent, long-lasting pattern, and are resistant to washing, wearing, and even high temperatures.

Sublimation on nylon is known to be incredibly durable and long-lasting. However, the exact temperature the sublimated pattern can sustain may vary depending on the type of nylon and ink used.

While sublimation on nylon can survive hot temperatures, it is still vital to wash and care for the item according to the manufacturer’s guidelines to ensure the sublimated design lasts as long as feasible.

Step-by-Step Guide for Sublimation on Nylon

Requirements:

- Nylon fabric or product with a polyester coating

- Sublimation ink

- Sublimation paper

- Heat press

- Computer with design software

- Cutting tools (such as scissors or a rotary cutter)

- Heat-resistant tape

Choose the right sublimation paper:

Selecting the proper sublimation paper for nylon is crucial. Sublimation papers of the highest grade will be specially coated to work with dye-sublimation inks. Because the coating encourages ink to adhere to the nylon fibers, the pattern lasts very long.

Select the design:

Pick a design with a high enough resolution to be printed using sublimation; low-resolution patterns can cause blurriness or visible pixels in the final product. If you’re making your design from scratch, use professional graphic design software like Adobe Photoshop or Illustrator.

Print the design on sublimation paper:

When printing the design, ensure the sublimation paper’s coated side is loaded into the printer. The arrow on the paper will tell you which side to load into the printer if you’re using sublimation paper. It’s also essential to choose printer-friendly dye-sublimation inks.

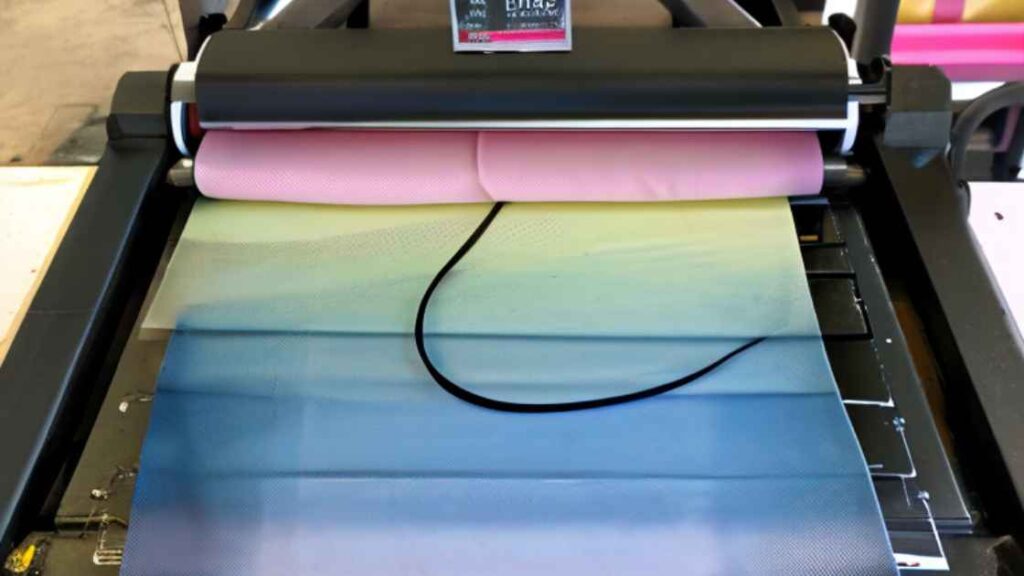

Preheat the heat press:

Get the heat press to the right temperature by heating it first. Depending on the type of nylon product you are sublimating, the ideal heat press setting is between 375°F and 400°F. Furthermore, the pressure should be set by the manufacturer’s instructions.

Prepare the nylon material:

Nylon material preparation is a necessary step before sublimation. Preheating the material for a few seconds before design transfer is recommended for the best results. To get the best possible transfer, you should also iron out any wrinkles or creases in the fabric.

Position the sublimation paper:

Sublimation paper should be placed on the nylon fabric after warming. Aligning the design properly is essential since it can affect the outcome if it is not done correctly. Use tape that can withstand high temperatures to keep the paper in place.

Apply heat and pressure:

Close the heat press and use the recommended pressure to provide heat. According to the product and the manufacturer’s instructions, you must keep the heat press in place for a specified time, ranging from 30 seconds to several minutes.

Remove the paper and check the results:

After the allotted time has passed, release the heat from the press and peel back the sublimation paper to reveal the nylon underneath. Verify the design’s transfer and color sharpness and vibrancy.

Finish and cure the design:

Once the sublimation process is complete and the design has been cured, the original vibrant colors will return. Curing the material in a high-temperature oven for the allotted time is required to complete the design. This process helps to permanently fix the dye, producing a pattern that will last a long time.

Check out this tutorial :

Considerations:

Nylon comes in various compositions and coatings, and a wide variety of nylon fabrics and goods are available. It is crucial to select a nylon product made for sublimation printing because not all nylons can be used for this purpose.

Coating:

Nylon products and fabrics need a polyester coating for sublimation on nylon to work correctly. The ink can migrate and stay on the fabric thanks to the coating. Ensure your nylon product has the appropriate coating by consulting the specifications or contacting the manufacturer.

Design:

Sublimation printing yields vivid, long-lasting images, but it’s vital to remember that the fabric color will affect the final result while sketching out your ideas. Fabrics with a lighter shade will highlight the design colors, while those with a darker shade will dull them down. Colors that clash with the fabric’s base will make your design look awkward.

Quality of materials:

The quality of the ink, paper, and press used in the process of sublimation on nylon can all impact the final product. You need to use high-quality tools and supplies to get the most remarkable results.

Related Post : Can you sublimate on Plastic?

Frequently Asked Questions

Q: Can I sublimate on dark-colored nylon materials?

The ink used in sublimation is transparent so that it won’t obscure the fabric’s color. The final product from sublimation on dark-colored nylon may not be as vivid or crisp as on lighter fabrics. You’ll get better results from sublimation on lighter-colored fabrics.

Q: Can I sublimate on waterproof nylon materials?

Sublimation can done on waterproof nylon fabrics. However, remember that the fabric’s waterproof coating can prevent proper ink transfer. Before committing to a complete transfer, it’s best to try it out on a scrap of fabric and see how the time, temperature, and pressure response.

Q: Is it necessary to use a particular type of ink to sublimate on nylon?

Nylon substrates do require a unique ink formulation for sublimation printing. Because of its artificial nature, sublimation on nylon requires a particular type of dye-sublimation ink. Typical sublimation inks only work with natural fibers like cotton and polyester, and they won’t adhere to nylon similarly.

Conclusion

In conclusion, you can sublimate on nylon, but care must be used to avoid damaging the fabric. Sublimation is best used on lighter nylon fabrics, as the ink is translucent and won’t obscure the fabric’s color entirely. To ensure a successful transfer, it is also necessary to utilize a particular type of ink developed to operate with synthetic materials like nylon and take the appropriate preparatory measures.