Have you ever been curious about screen printing? Have you seen a shirt, poster, or other item with an image and wondered how it got there? If so, then you’ve come to the right place! Screen printing is a popular method used to create images and designs on any type of material. Let’s explore what screen printing is, how it works and its many uses.

Screen printing has become widely popular for customizing apparel such as t-shirts and hats. It’s also commonly used for promotional materials like signs and banners, packaging designs and more. Now that you know what screen printing is all about let’s dive into how it works!

What Is Screen Printing And How Does It Work?

Screen printing is a popular form of printing used for both commercial and artistic purposes. It involves pushing ink through a mesh screen onto a substrate or fabric to create the desired design.

This versatile process can be used to print on many different types of surfaces, including t-shirts, paper, metal, plastic, wood, and more. The process of screen printing starts with creating the stencil or “screen” from which the ink will pass through.

This is done by transferring a design onto a special material such as silk or polyester. The design is then blocked out in areas that are not to be printed by using an emulsion or other light-sensitive material.

Once the screen is created, it must be prepped for use by stretching it tightly over an adjustable frame and cleaning it with special solvents.

Related: Sublimation Vs Screen Printing: Ultimate Comparison (2023)

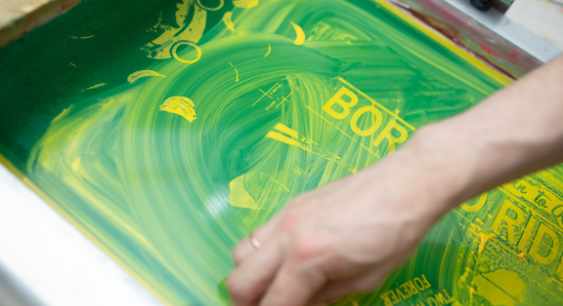

After this process is complete, the printer will place their substrate beneath the screen and secure it into place before applying ink onto one side of the mesh opening. As they draw the squeegee across the surface of the screen, ink will pass through the open areas of the mesh and transfer to their substrate below.

Finally, after allowing sufficient time for drying and curing, they can remove their substrate from underneath the screen to reveal their completed print job!

Materials Used For Screen Printing

The materials used to screen print typically consist of one or more screens, ink, and a substrate. The screens are made from a tightly woven fabric, such as polyester or nylon, and have an image burned onto them.

This image is then coated with a light sensitive emulsion which hardens when exposed to ultraviolet (UV) light. The emulsion creates the stencil that will be used to print the desired design. Ink is then pushed through the stenciled screen onto the substrate below it with either a squeegee or a roller.

Also Read: 8 Best Methods to Remove Screen Printing.

The most common substrates used for screen printing are T-shirts, paper products, glassware, metal items, plastic items and other fabrics such as canvas and vinyl.

Each of these surfaces requires different inks and techniques for successful printing results. For instance, if you are using fabric as your substrate you will need to use water-based or discharge inks that will not damage or bleed into the fibers of the fabric being printed on.

On the other hand if you are printing on metal you may need to use special adhesives that allow for adhesion between the substrate and the ink being used.

Equipment Required For Screen Printing

Screen printing requires a few pieces of equipment.

Screen: The first and most important is the screen itself, which acts as a stencil for your design. This is made of a mesh fabric stretched over a metal frame.

Coating (Photo Emulsion): You’ll also need some kind of emulsion or photo-sensitive material to coat the screen with, which will then harden when exposed to UV light.

Squeegee: Finally, you’ll need a squeegee, ink, and some kind of substrate onto which you’ll be printing – such as paper, fabric or wood.

In addition to the equipment mentioned above, there are many other tools that can help make your screen printing process easier and more efficient.

These include an exposure unit (used to expose the emulsion), various types of frames, scoops, scoop coaters and flood bars (used to spread the ink evenly over the screen).

Additionally, some people may want to use specialised inks or other materials such as varnishes or glitters for their project. With all these tools at your disposal, you’re ready to start screen printing!

Step By Step Process Of Screen Printing

Moving on from the equipment required for screen printing, let’s take a look at the process involved in screen printing.

1) The first step is to prepare the design that needs to be printed. This design is then transferred onto a polyester or nylon mesh screen.

2) Once this is done, the next step is to attach this screen onto the frame.

3) After that, it is time to set up and prepare the ink that will be used for printing. This includes mixing colours and making sure it has a suitable consistency.

4) Next step involves stretching the mesh tautly over the frame and creating a stencil of your design by blocking off certain areas with a special emulsion, which prevents ink from being printed on those areas.

5) Once this stencil has been created, it’s time to start printing! The printer pushes ink through the mesh onto your garment with a squeegee, resulting in stunning prints on fabric or other surfaces.

Pros And Cons of Screen Printing

| ↑Pros | ↓Cons |

|---|---|

| High quality and long-lasting prints | Limited color options |

| Works well with a variety of materials, including fabric, plastic, and metal | Not ideal for complex designs with fine details |

| Cost-effective for large orders | Setup costs can be expensive for small orders |

| Can achieve opaque and vibrant prints | Not as eco-friendly as digital printing |

| Durable and able to withstand repeated washing or use | Requires separate screens for each color |

| Can print on a variety of sizes and shapes | Limited print resolution compared to digital printing |

Different Types Of Screen Prints

There are multiple types of screen prints, which are differentiated by the type of material used for the stencil and the method of application. Here’s an overview of the different types of screen prints:

Flatbed Screen Printing: The screen is maintained in place while the printing substrate (such as paper or fabric) is fed underneath it. A squeegee is then used to push the ink through the screen, resulting in a smooth and even print.

Rotary Screen Printing: Rotary screen printing involves wrapping the screen around a cylindrical drum that rotates as the printing substrate is passed through it. This enables substantially higher printing speeds, making it perfect for mass production.

Dishcharge Screen Printing: Discharge screen printing employs a specific sort of ink that eliminates dye from the fabric rather of adding color to it. As a result, the design is more natural and breathable, making it popular for printing on cotton and other natural fabrics.

Water-based Screen Printing: This approach use eco-friendly water-based inks to produce softer prints. They are suitable for making high-quality, intricate prints on light-colored materials.

Plastisol Screen Printing: Plastisol ink, a sort of plastic-based ink that is heat-cured onto the cloth, is used in this procedure. It generates brilliant and long-lasting prints, making it a popular choice for printing on dark textiles and manufacturing products.

CMYK Screen Printing: This method involves printing a full-color image with four different hues (cyan, magenta, yellow, and black). It is frequently employed in the printing of pictures and other detailed images.

What Is The Difference Between Spot Color And Process Color Screen Printing?

Spot color screen printing involves using one single ink color on the surface being printed. This type of screen printing produces bold colors that can easily be seen from a distance.

Process color screen printing uses multiple inks to create an image or design. The inks are layered on top of each other to create the desired effect. This type of printing allows for more detailed and complex images to be printed than with spot color printing.

The colors created by process color screen printing are usually more subtle than those created by spot color printing, but still provide a vibrant effect. Both types of screen printing are great for creating high quality prints that will last for years to come.

How Many Colors Can Be Used In Screen Printing?

Screen printing is a versatile method of printing that uses stencils to create designs on fabrics and other materials. With screen printing, a single color is applied to a fabric at a time, as the colors are printed one after another.

However, there is no limit to the number of colors that can be used in screen printing. Depending on the complexity of the design and the desired outcome, anywhere from one to twelve colors can be used.

Using more than one color in screen printing creates an interesting visual effect called “halftones”. This technique allows for subtle gradations in color and tone, creating a smooth blend between two or more colors.

The use of halftones also gives you full control over the process, allowing you to adjust the color intensity and achieve an accurate representation of your design.

With multiple colors available, you can create complex designs with intricate detail and bright colors that stand out when printed onto fabric.

How Can I Care For My Screen Printed Products To Ensure Longevity?

To ensure that your screen printed products last as long as possible, there are some simple steps you can take.

One way to make sure your screen printed items stay in top condition is to wash them inside out using cold water. This helps to preserve the colors and prevent fading.

You should also avoid using harsh detergents or fabric softeners on your screen printed items. Additionally, it’s best not to put them in the dryer, but rather air dry them instead.

What Are Some Common Mistakes To Avoid In Screen Printing?

The first mistake to avoid is using the wrong mesh count for the job. Mesh count refers to the number of threads per inch in a screen, and incorrect mesh counts can cause problems with print quality. It’s important to use the right mesh count for each project.

Another mistake is not properly stretching the screen before printing. When screens are not stretched correctly, they will warp or sag during printing, resulting in smudged prints.

It’s also important to make sure that the right type of ink is used – most printers use plastisol ink, but some specialty inks may require different types of mesh or special care during setup.

Finally, it’s essential to carefully clean screens after each print run so that there aren’t any residue left that could cause problems with future prints. Taking these precautions will help ensure high-quality prints every time.

Frequently Asked Questions

Q: How long does it take to screen print?

The length of the screen printing process varies based on factors such as the number of colors used, the complexity of the design, and the number of things printed. A screen printing project can take anywhere from a few hours to several days to complete.

Q: How can I get my artwork ready for screen printing?

Screen printing artwork should be generated or converted to a vector-based format, with each color divided into its own layer. To guarantee proper printing, the design should also be adjusted to the desired print dimensions, and any text should be converted to outlines.

Q: What are some other printing processes to think about?

Digital printing, sublimation printing, heat transfer printing, and embroidery are some alternatives to screen printing. Each method has advantages and disadvantages, and the optimum solution will be determined by the specific project requirements.

Q: Can both bright and dark colored fabrics be screen printed?

Yes, both light and dark colored fabrics can be screen printed. However, alternative approaches, such as utilizing an underbase layer to guarantee that the colors show up effectively, may be required when printing on dark textiles.

FINAL THOUGHTS

In conclusion, screen printing is a great way to produce artwork, designs, and logos onto a variety of materials. It’s an incredibly versatile printing technique that can be used for t-shirts, hats, bags, and more. With the right materials and equipment, it’s possible to produce professional-looking results with limited effort.